If you have comments, questions or interest in the technology described in the following article, please contact us at:

Email: cometrue@icometrue.com

Logic Drive

iCometrue proposed the prospect and dream of “Logic Drive” in 2016, in hope of providing a possible alternative for IC chip design talents with limited funding. By raising just less than a couple hundreds of thousands (or a few millions) US dollars, the IC chip design talents could start-up IC chip design companies to implement their innovations in IC chip fabricated based on advanced semiconductor process technologies (for example, technology nodes of 10, 7, 5, 3 nm or below) of foundry fabs (such as TSMC, Samsung, and Intel). The Logic Drive provides a way for the 99% of common public to participate in the game of the wealthy 1%.

“Logic Drive” is based on a concept of “software-defined hardware”. It uses the FPGA (Field Programming Gate Array) chip fabricated by the advanced semiconductor process technologies (for example, technology nodes of 10, 7, 5, 3 nm or below) as its foundation and consists of the following three major concepts or technologies:

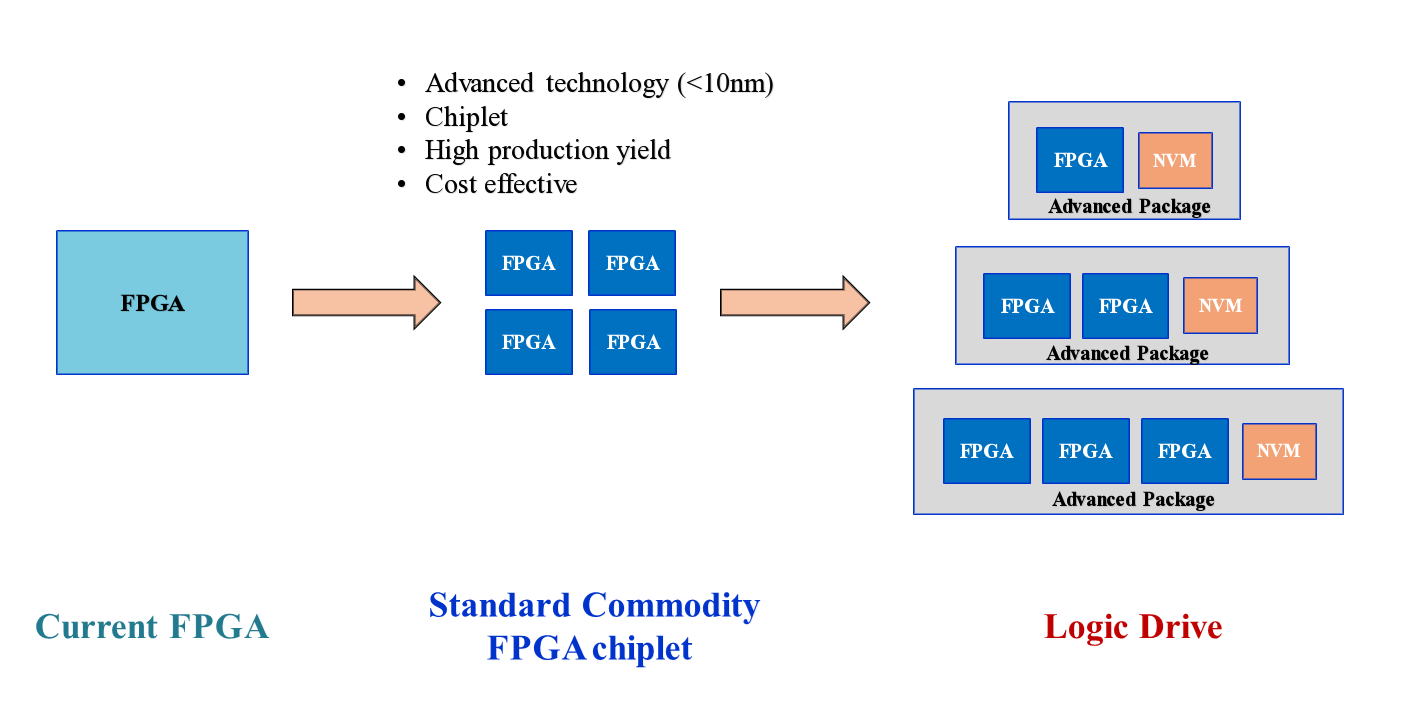

I. Standard Commodity FPGA Chiplet

FPGA chiplets contain transistors made by the technology more advanced than 10nm technology node such as the FINFET (in mass production now) or GAAFET (under development now). The transistors fabricated using the advanced semiconductor process technologies (for example, technology nodes of 10, 7, 5, 3 nm or below) have the advantages of higher speed and lower power consumption (in GAAFET, the operation voltage could be even lower than 0.5V). The advanced process technology nodes greatly increase the transistor density on a chip allowing smaller chips to contain the number of transistors same as or more than that on the current large size chip. One such FPGA chiplet contains as many as several tens of billions of transistors. The smaller chip size improves production yield and also reduces the manufacturing cost. iCometrue proposed the standardization of FPGA chiplet. The standardization items include chip size, the circuits and quantity of logic elements, the layout, quantity and specifications of I/O (including driving capability and impedance, inter-chip communication). The standardization greatly reduces the cost of chiplets and turns FPGA chip into standard commodity FPGA logic chips, just like DRAM or flash standard commodity memory chips. The logic chip industry may, in some portion, become a standard commodity logic industry just like the standard commodity memory industry.

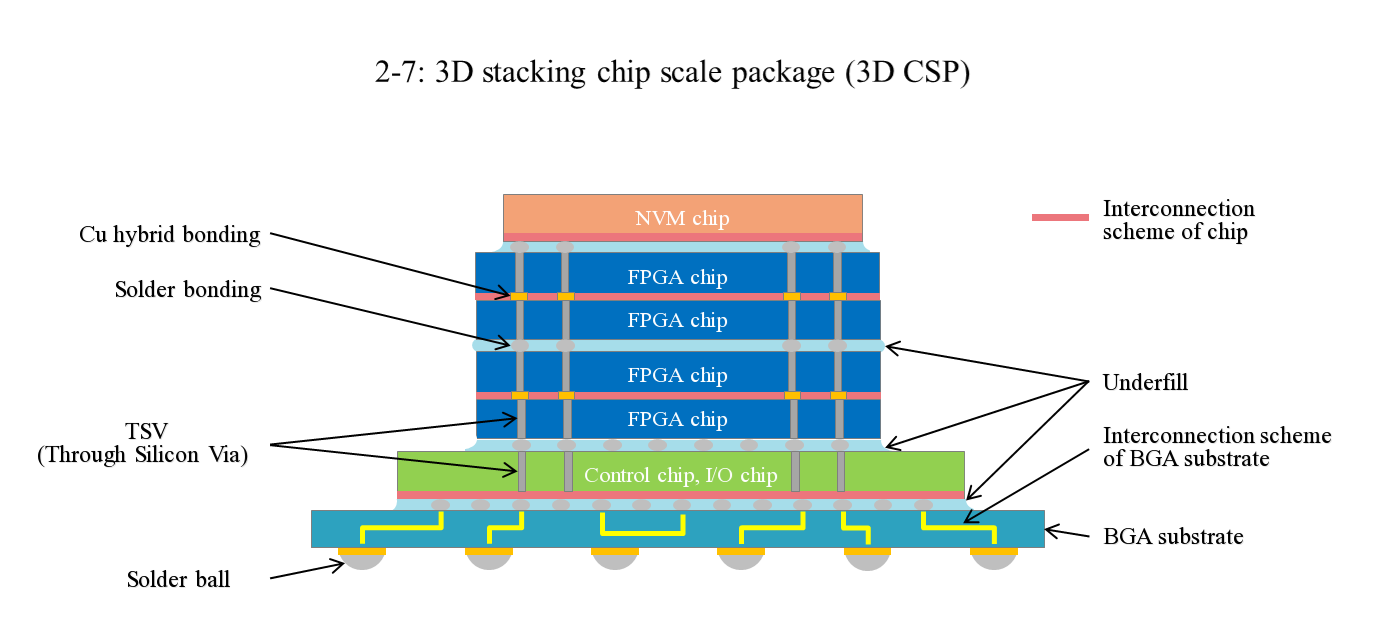

II. Multichip Package contains one or multiple standard commodity FPGA Chiplets and a Non-Volatile Memory Chip

The Logic Drive is a multichip package containing one or multiple FPGA chiplets and a Non-Volatile Memory (NVM) chip, in which the NVM chip is used to store the programming codes for configuring the logic circuits of the FPGA chiplets. With the NVM chip in the same package, it turns the FPGA chiplets within the Logic Drive into a non-volatile element and the Logic Drive could be used like an ASIC chip. An innovative IC designer may implement his innovations cost-effectively by programming his innovation into the Logic Drive made by the advanced semiconductor process technologies (for example, technology nodes of 10, 7, 5, 3 nm or below). Furthermore, the hardware circuits of the FPGA IC chip in the Logic Drive could be re-configured by software for a new computing logic application, and become non-volatile elements by storing the re-configuration data in the non-volatile flash memory chip packaged in the same Logic Drive. The Logic Drive is now like the Solid-State Drive or Solid-State Disk (SSD); the only difference is that SSD is for storing data memory, while Logic Drive is for storing computing logic.

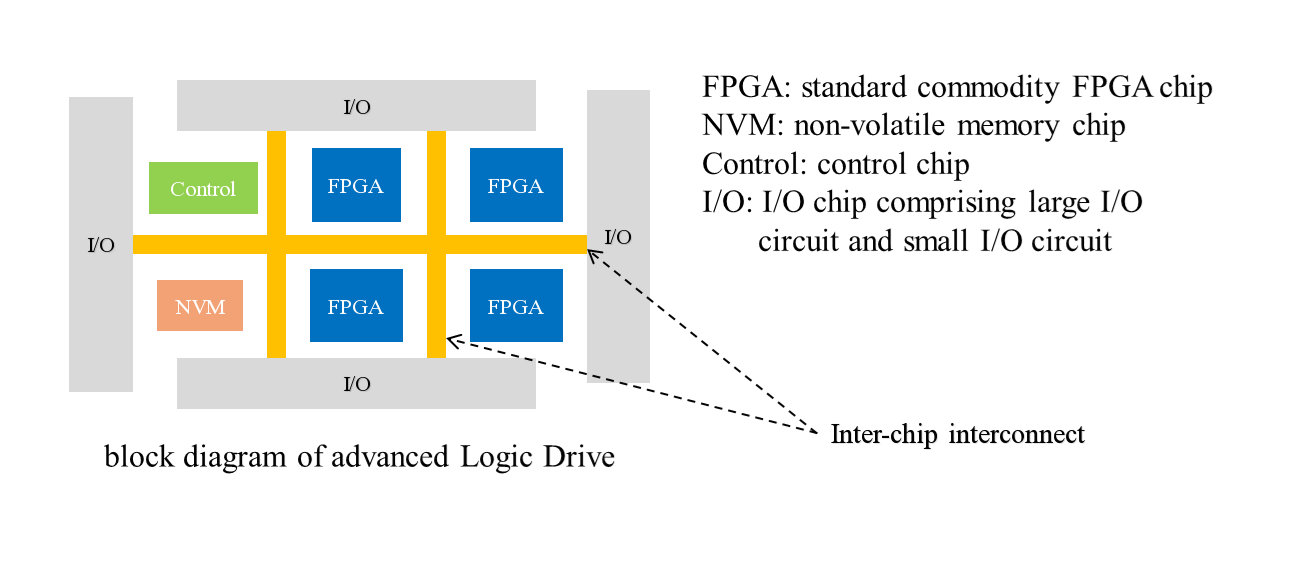

An advanced Logic Drive further adds a control chip and one or multiple I/O chips into the Logic Drive: (i) The control chip manages the interconnection between the FPGA chiplets within the Logic Drive, the read-write operation of FPGA chiplets to the NVM chip, and controls the operation between the Logic Drive and external circuits; (ii) The I/O chips consist of small I/O circuits and large I/O circuits. The small I/O circuits are used for interconnection between the FPGA chiplets, control chip and NVM chip within the Logic Drive. The large I/O circuits connect the Logic Drive to external circuits.

iCometrue pioneered a design of moving the control circuits and the large I/O circuits, both originally included in the FPGA chip, into the control chip and I/O chips packaged in the Logic Drive. As a result, most of the area of the FPGA chip is used for the arrays of logic cells, so that the layout of logic circuits will be similar to DRAM cell arrays. This further reduces the size of FPGA chip and makes the FPGA chip standardization easier.

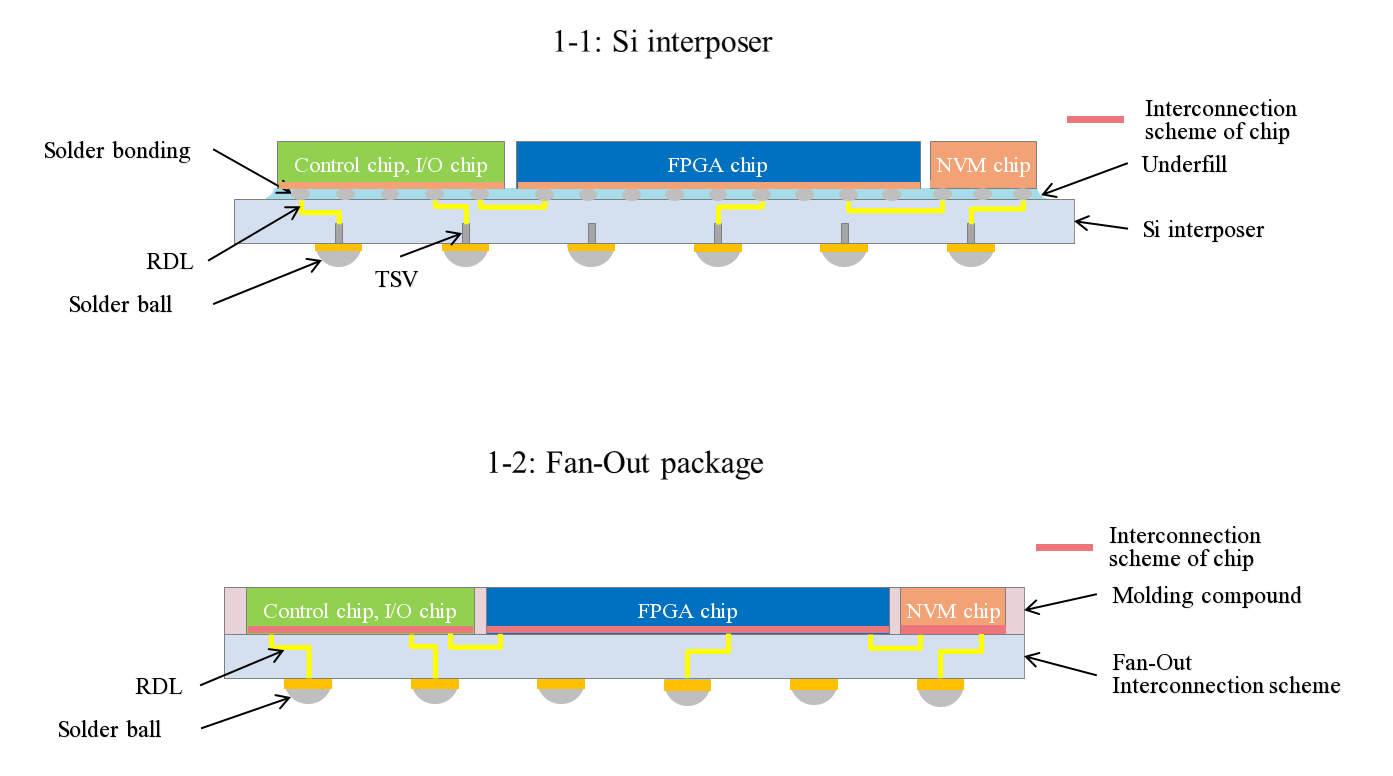

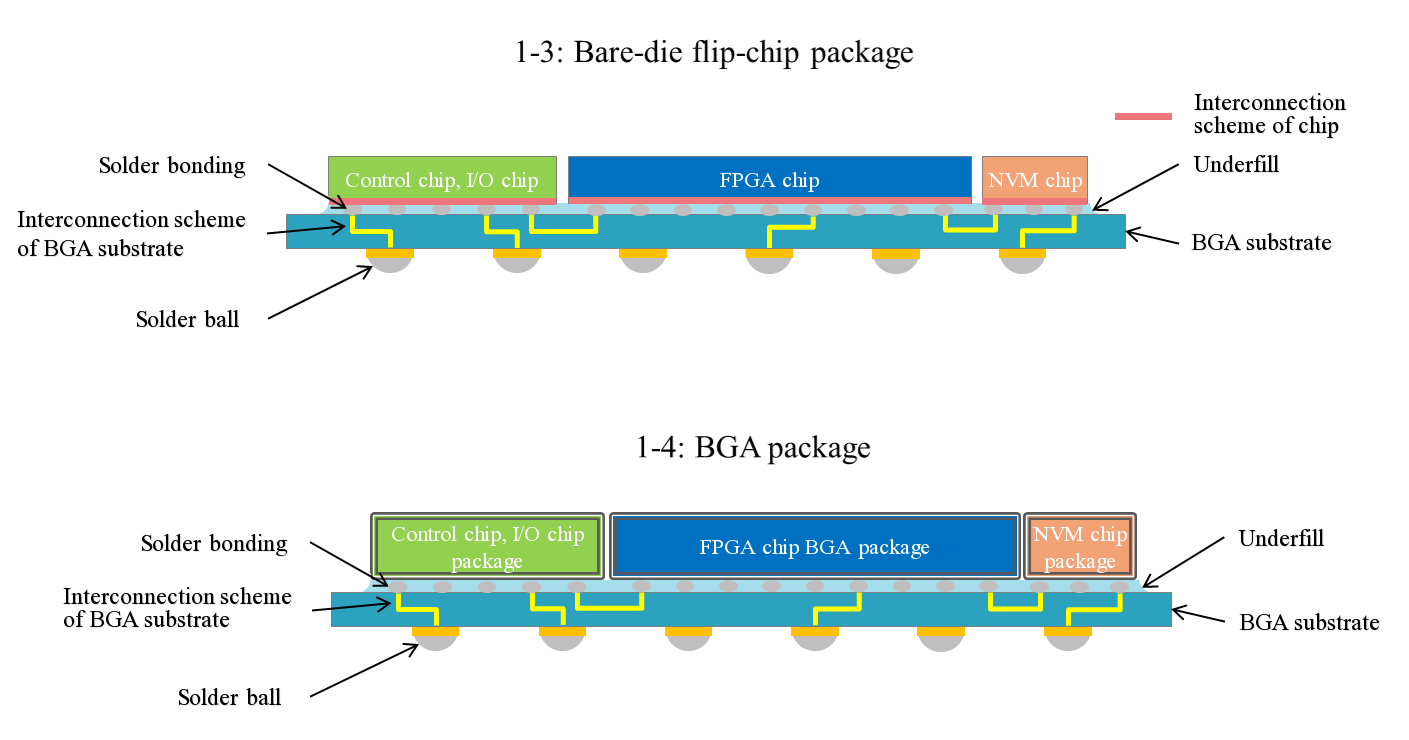

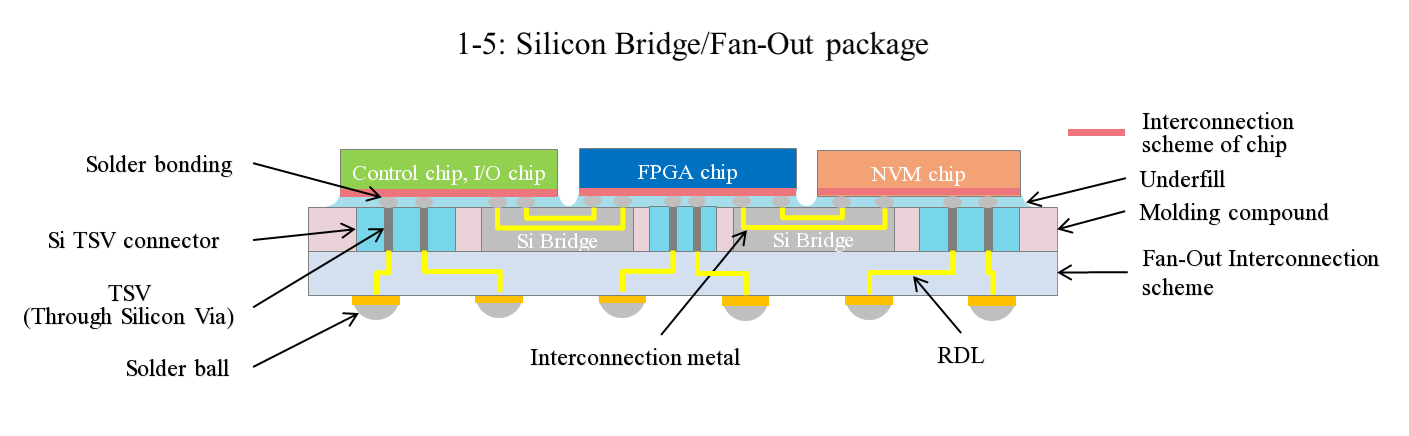

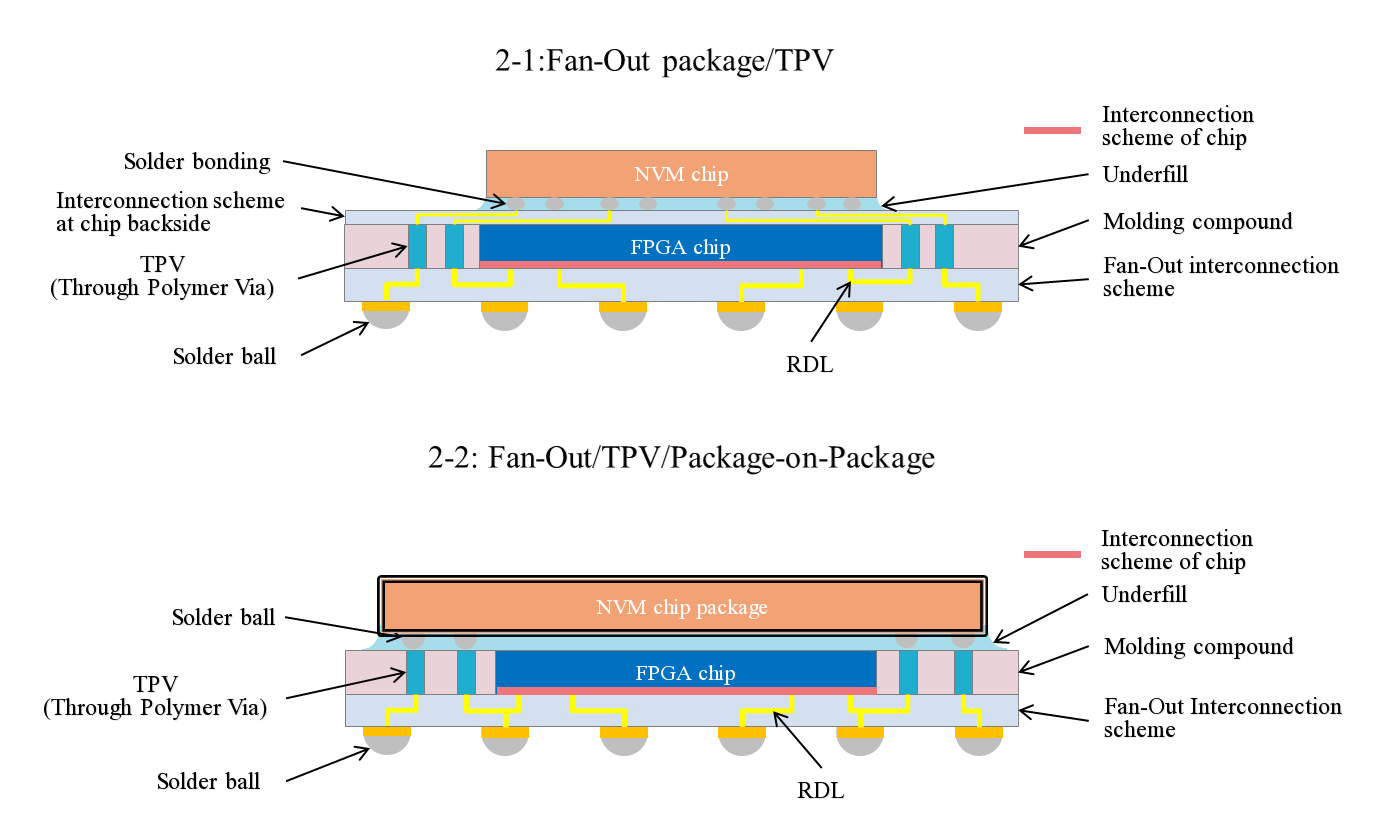

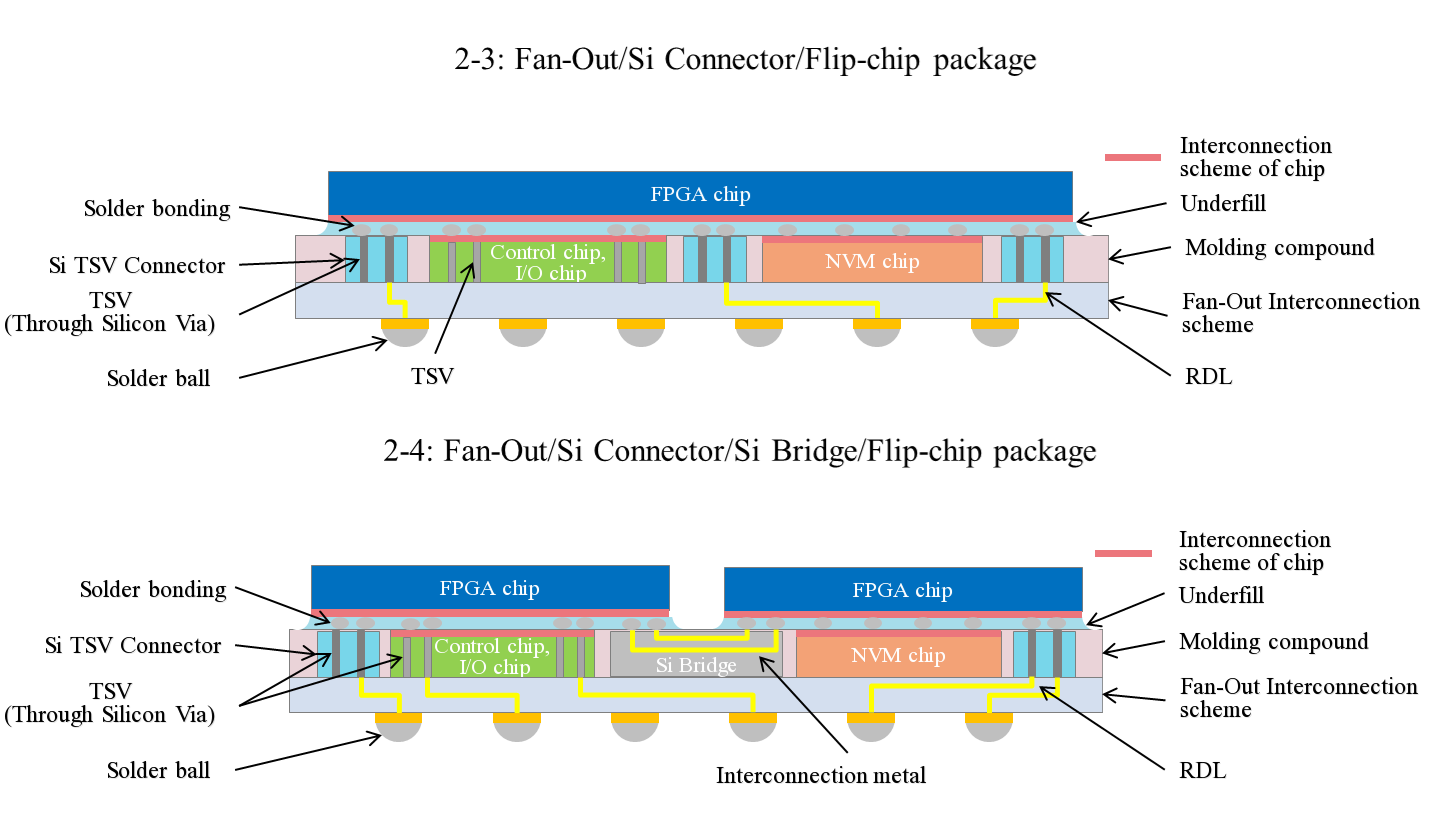

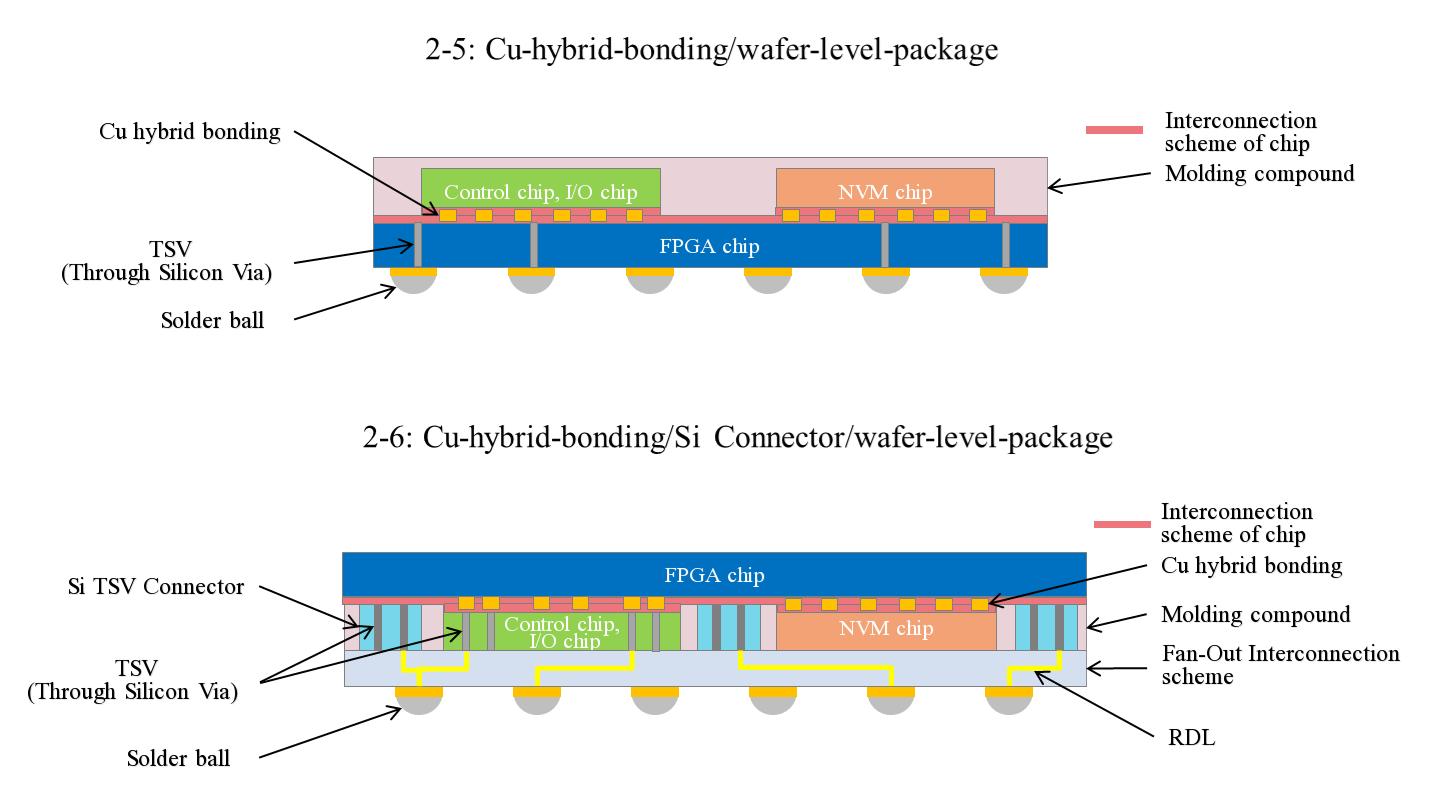

The Logic Drive mentioned above are fabricated by using advanced multichip packaging technologies to form the 2D planar package or 3D stacking package. The structures of the advanced multichip packages used for Logic Drive are shown below:

1. Logic Drive in 2D Planar Package

2. Logic Drive in 3D Stacking Package

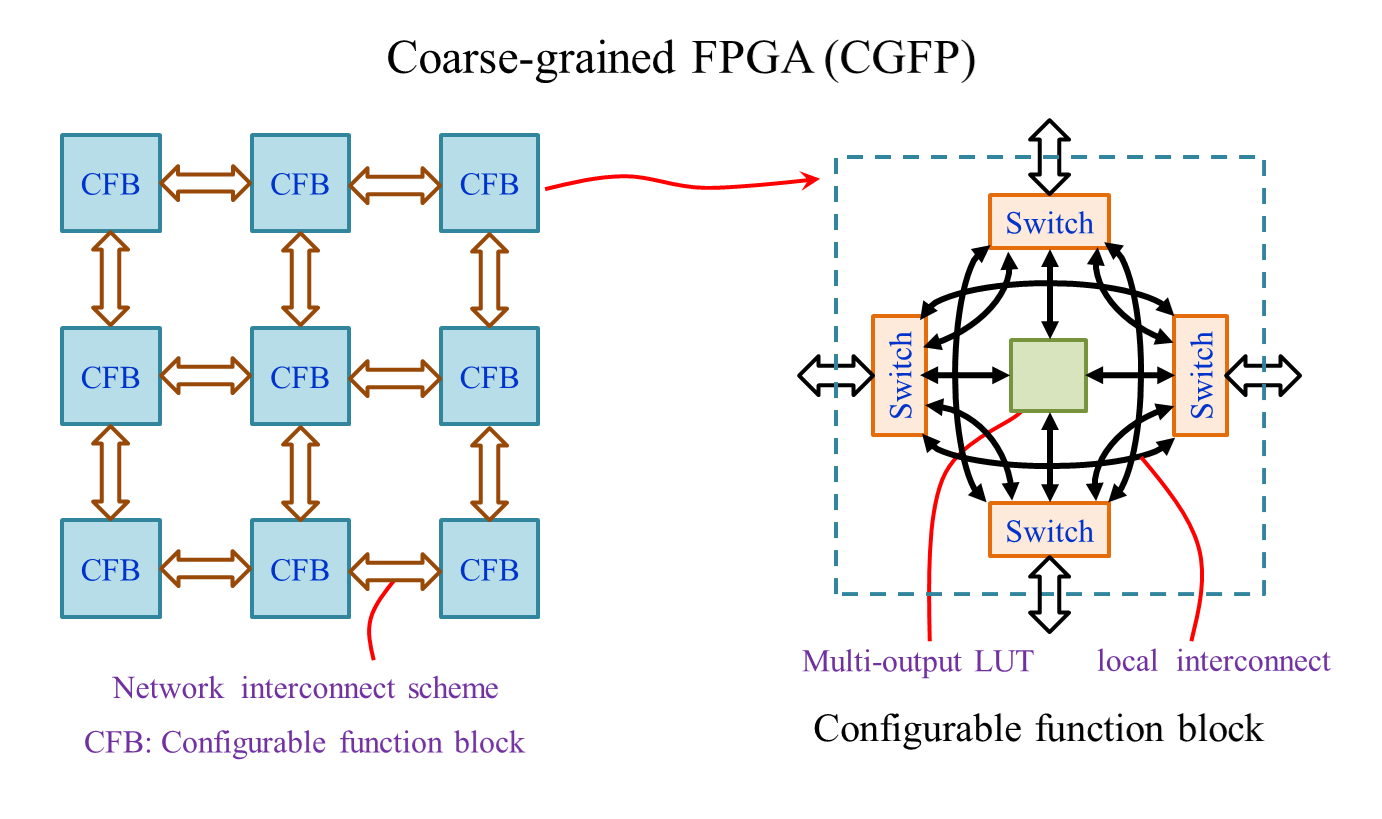

III. New FPGA Architecture and Algorithm

The way that the FPGA chip provides the capability of configuration and re-configuration by programming methods to alter the hardware circuits, is similar to the way that the human’s brain provides the capability of the plasticity and integrality for powerful thinking. The capability of configuration and re-configuration of the FPGA chip is naturally suitable for the applications in artificial intelligence (AI), using software programming to configure and re-configure the hardware circuits for executing AI algorithm. The future development of Logic Drive, made based on FPGA chips, may be greatly bio-inspired by human’s brains and learned from the plasticity and integrality of human’s brains. New ground-breaking architectures and algorithms for FPGA IC chips, therefore Logic Drives, may emerge, especially in artificial intelligence. It is encouraging that some new architectures and algorithms for FPGA IC chips are coming up recently. For example, the Coarse-Grained Reconfigurable Architecture (CGRA) using the multiple-output Look-Up Table with the Coarse-Grained architecture and the Programmable/Configurable Interconnection Network to form Coarse-Grained FPGA (CGRA FPGA). The CGRA FPGA chip results in higher speed and lower power consumption. The field programmability of FPGA chips will rise to prominence when applied in new areas such as the metaverse and autonomous vehicle.

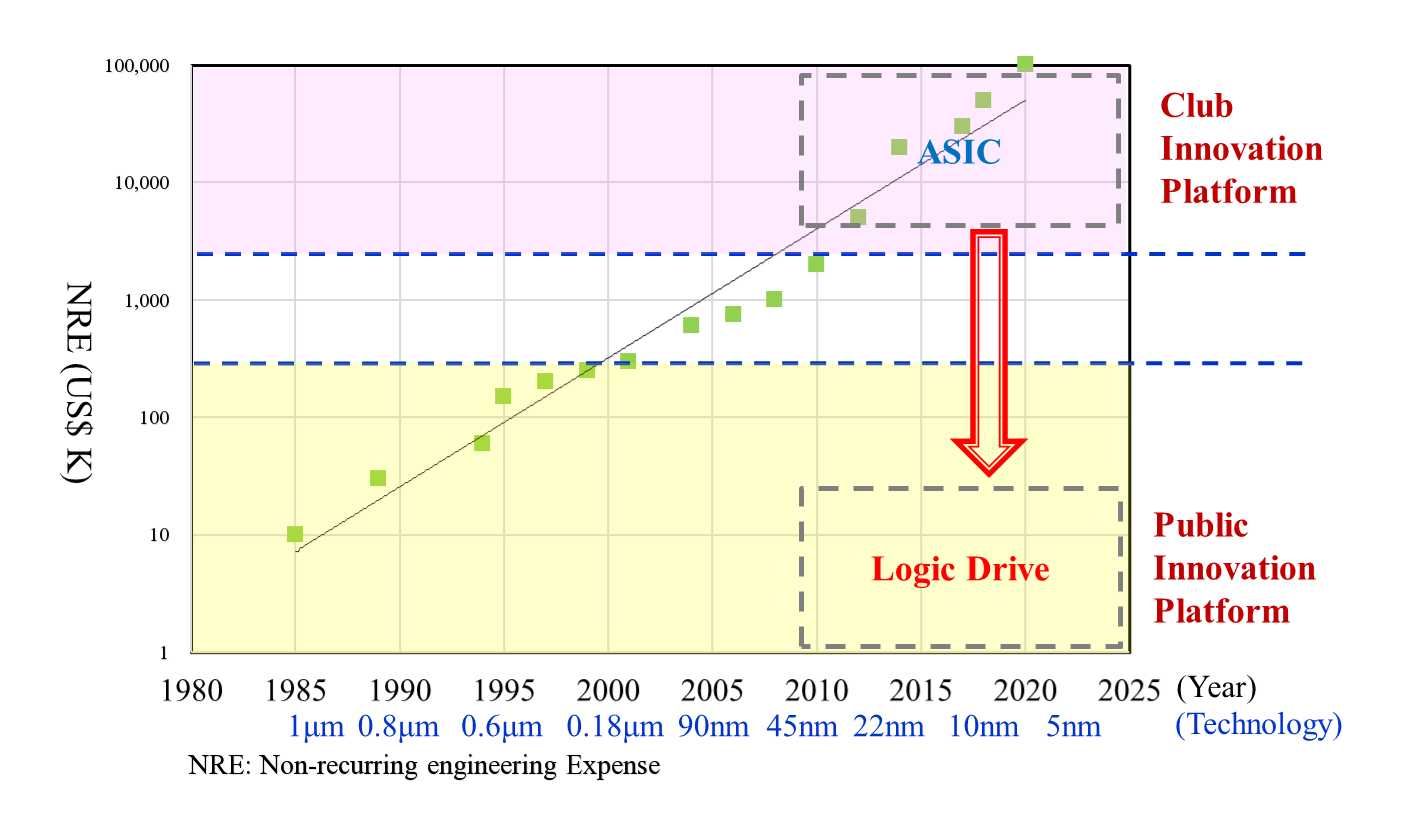

Logic Drive provides a “Public Innovation Platform” with equal participation opportunities

Logic Drive provides the talents with limited funding equal opportunities to participate in the utilization of the advanced semiconductor process technologies (for example, technology nodes of 10, 7, 5, 3 nm or below). With Logic Drives, the best minds of innovated IC chip designers would be competing to design the best, most useful and powerful IC chips (though by software programming) to create disruptive products with disruptive architectures and algorithms and to accelerate the technology development in the semiconductor industry.

In early 1990’s, a creative and talented IC designer could start-up an IC design company with just hundreds of thousands or one to two million US dollars and use TSMC’s 1.0 to 0.35 m manufacturing processes to realize their design creations. TSMC’s fabs were then known as a “Public Innovation Platform”. Many of today’s IC design companies, such as NVIDIA, Qualcomm, Broadcom, Marvel, Realtek, and hundreds and thousands of others all started this way back then. These startup companies came to defeat the world’s IDM (Integrated Device Manufacturer) semiconductor industry giants and, more importantly, brought about the birth of the life-changing iPhone 1 in 2007, which used many of the chips designed by the startup IC design companies and manufactured by TSMC. You could say that TSMC (a Public Innovation Platform provider) was, in fact, the hero behind the scenes in the story of the iPhone 1.

However, one could argue that TSMC no longer maintains the early ideals of its “Public Innovation Platform” today, now resembling more of a “Club Innovation Platform”. Case in point, even a set of 10 nm masks now costs about three million dollars, and roughly nine million dollars for 7 nm masks. The non-recurring-engineering (NRE) expense for developing a 7 nm chip is in the tens or hundreds of millions of dollars. Only system companies like Apple or major IC design companies like Qualcomm, MediaTek, NVIDA and AMD have the resources to participate and buy into the astronomically expensive game of the advanced semiconductor manufacturing process (for example, process in technology nodes of 10, 7, 5, 3 nm or below).

TSMC has transformed into the “Club Innovation Platform”. However, if the foundry fabs (for example, TSMC, Intel, Samsung) with the capability of technology nodes advanced to less than 10 nm could provide a portion of the advanced technology (10, 7, 5, 3 nm or below) production capacity and manufacture Standard Commodity FPGA Chiplet for Logic Drive, then the 99% of the innovators can also participate in the game of using the advanced technology process (10, 7, 5, 3 nm or below). Their contribution to human civilization will surely leave a mark in the history books.

Logic Drive fulfills the social responsibilities of environmental protection

Logic Drive could also fulfill the social responsibilities of protecting the environment and being eco-friendly. For example, regarding Apple’s commitment to protecting the environment, if iPhone uses Logic Drive, it would allow users to re-configure the hardware, add new functions and upgrade their iPhones without purchasing new phone devices. The re-use of Logic Drive could extend the lifespan of phones and reduce the usage of water, electricity, and materials from producing phones. Together, with the decrease of waste phone disposal, it will be greatly helpful for environmental protection.